Increases Production – Reduces Wear – Decreases Maintenance Costs

Using ProOne’s XPL+® Lubrication Technology which bonds to metal, dramatically reducing friction and wear, ProFlow was developed for the Oil & Gas Production market to solve the problem of inefficient production and untimely wear and failure.

Progressive Cavity Pumps

- Immediate reduction in torque of 25-40%

- Allows for 33% or more increase in RPM and additional fluid volume

- Reduces the electrical load on the pump system by 20% or more

- Bonds to sucker rods, tubing, plungers and other metal parts which reduces friction and untimely wear

- Extends maintenance cycles and lifespan of treated pump system parts

- Acts as a conditioner and lubricator in the PC pump’s stator

- Helps encapsulate sand and other foreign debris to reduce abrasive damage to the composite stator

- Helps clean perfs enabling better flow of the production fluid and less torque moving the fluid up the well and out to the production line

Rod Pump Operations

- Reduces torque and friction

- Extended lifespan on moving parts due to the bonding nature of XPL+ lubrication

- Reduces electrical draw and less load on the system due reduced drag

- Cleaner perfs, more efficient transfer

- Less wells servicing

Gas Condensation Production Operations

- Extends life of fast-failing surface pumps in gas condensate production

- Reduces pump replacement, downtime, and labor costs

- Pumps immediately run smoother and quieter

Case Studies

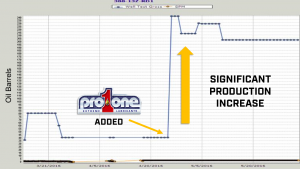

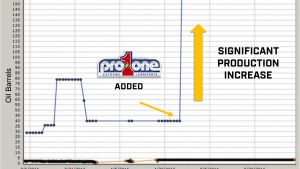

This significant increase in production in a 30 day period is due to a 70% + reduction in friction and a 20% reduction in load. Both wells had similar long term results. Both wells were experiencing high friction and load in highly deviated wells. They were still prone to rod stick and frequent service even at the slowest operating speeds, and using flexible rod / big RotoFlex units.

Other results noted include:

- Reduced Energy Consumption

- Reduced Flow line Pressures Increased Laminar Flow

- Smoother Operation

Problem: several deviated wells with high rod load and friction contributing to slow operating speeds and production volumes well below potential.

Solution: Began treatment with ProFlow, our biodegradable production lubricant which reduces friction, torque, drag, energy consumption, and flow line pressures.

Result: The friction was reduced by over 70%, the pump speed increased to its max speed, rod load dropped by 20%, and production volume went from 60 BPD to 200 BPD and held that volume for the duration of the treatment period